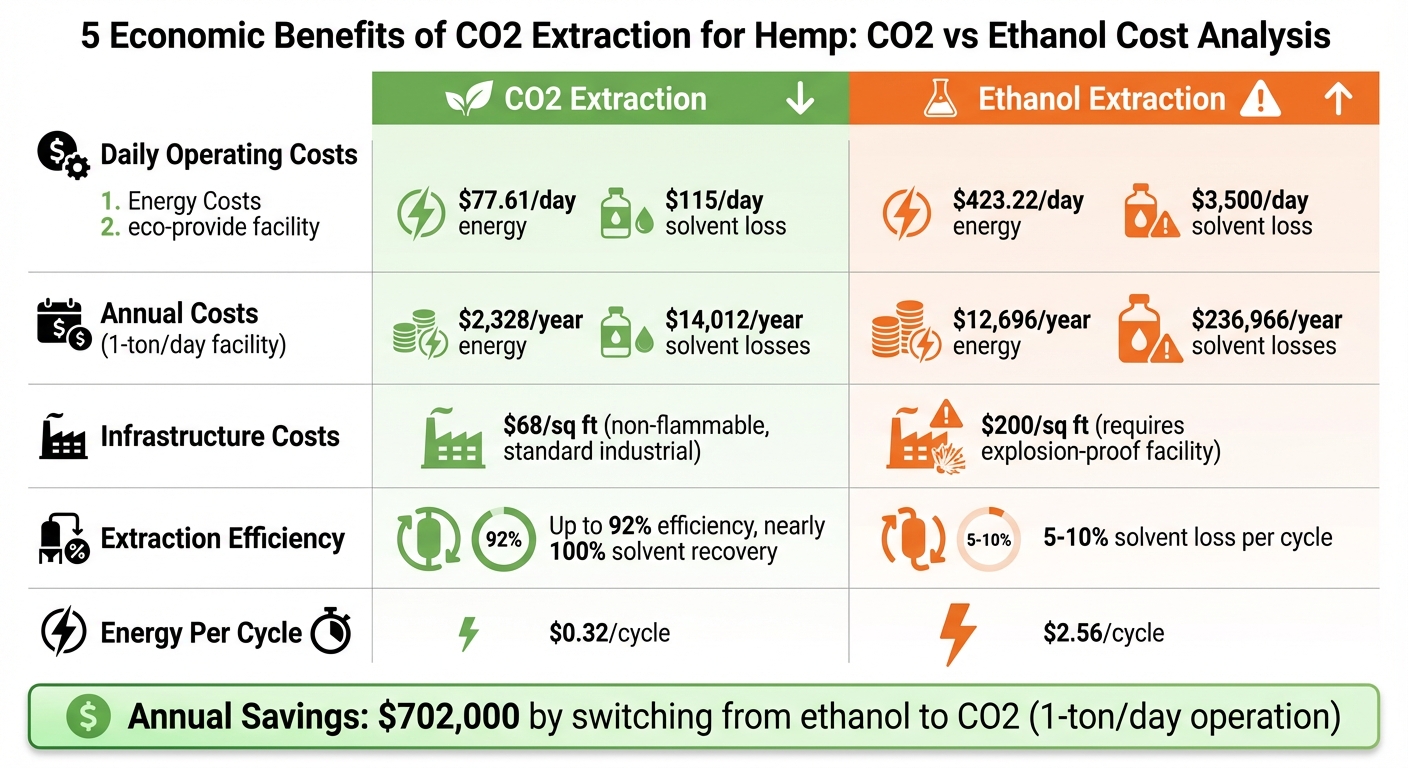

CO2 extraction is saving hemp producers big money while boosting product quality. Here’s why it’s the smarter choice:

- Lower Costs: Daily energy costs for CO2 average $77.61, compared to $423.22 for ethanol. Solvent losses? CO2 runs at $14,012/year, while ethanol burns through $236,966/year.

- Higher Yields: CO2 systems recover nearly 100% of solvents, maximizing cannabinoid output up to 92% efficiency.

- Cheaper Infrastructure: Non-flammable CO2 slashes facility costs to $68/sq ft, versus ethanol’s $200/sq ft.

- Energy Efficiency: A 1-ton-per-day CO2 setup costs $2,328/year in energy, compared to ethanol’s $12,696/year.

- Cleaner Products: CO2 extracts are solvent-free and residue-free, meeting consumer demand for pure, premium hemp goods.

CO2 extraction isn’t just cost-effective - it’s redefining how hemp businesses stay competitive. Lower bills, higher yields, and cleaner products make it the go-to method for scaling up without breaking the bank.

21 + only. Hemp-derived; contains < 0.3 % Δ-9 THC (dry weight). Effects may be delayed up to two hours. Check local laws.

CO2 vs Ethanol Hemp Extraction: Cost Comparison Infographic

10 Reasons Ethanol Extraction is "Better" than CO2 Extraction!?

sbb-itb-3a0b05a

1. Lower Operational Expenses Through Efficient Extraction

CO2 extraction significantly trims costs, especially when it comes to solvents. Bulk CO2 is incredibly affordable at about $0.04 per pound, compared to food-grade ethanol, which ranges from $16 to $35 per gallon. The gap only grows when you consider solvent loss. Ethanol systems typically lose 5% to 10% of their solvent during each cycle as it sticks to the biomass. For a facility processing one ton of biomass daily, this translates to approximately $3,500 in daily solvent loss for ethanol, compared to just $115 for CO2. Beyond solvent costs, CO2 extraction also offers savings in facility design.

The infrastructure needed for CO2 extraction is far less demanding. Since CO2 is non-flammable and inert, facilities can operate under standard industrial classifications. On the other hand, ethanol-based operations require explosion-proof facilities equipped with fire suppression systems and specialized ventilation. This difference pushes infrastructure costs to around $200 per square foot for ethanol facilities, compared to just $68 per square foot for CO2 facilities. Insurance costs follow a similar trend, with CO2's safer profile leading to lower premiums.

"CO2 extraction dramatically lowers operating costs." – extraktLAB

Post-processing costs also take a hit with CO2. Ethanol tends to extract chlorophyll and waxes, which require costly filtration steps to remove. CO2, however, avoids pulling chlorophyll altogether, thanks to its precision. Its tunability allows operators to target specific compounds, cutting out unnecessary post-processing steps.

Even waste disposal becomes more economical. Biomass processed with ethanol is classified as hazardous waste, requiring regulated disposal and transportation fees. In contrast, CO2-extracted biomass remains clean enough to be repurposed as food-grade material or even animal feed, turning what would be a cost into a potential source of revenue.

2. Higher Extract Yields Increase Revenue Per Harvest

CO2 extraction brings out the best in every pound of hemp, delivering an impressive efficiency rate of up to 92%. With yields spanning from 51% to 100%, and high-CBD extracts reaching concentrations of 449 mg/g, this method stands out for its ability to maximize output. The secret lies in CO2's unique properties during the extraction process.

When CO2 enters its supercritical state, it behaves like both a gas and a liquid. This dual nature allows it to penetrate plant cells deeply and dissolve cannabinoids effectively. Beyond its extraction power, it also speeds up the process. CBD-heavy hemp strains can be processed two to three times faster than high-THC varieties while still delivering the same raw oil yield.

"Of the high-CBD strains we process, total extraction run time is two- to three-fold less than their high-THC counterparts, yet achieves the same yield of raw oil." – Rachel Loeber, Chief Scientific Officer, Leafline Labs

Another advantage of CO2 extraction is its flexibility. By fine-tuning parameters like temperature and pressure, and even introducing 10% ethanol as a co-solvent, yields can increase by 30%. This approach can concentrate extracts to contain as much as 40% CBD, often achieving purity levels as high as 95%. Such high-quality extracts are highly sought after, especially in the health and nutraceutical markets, where premium pricing is the norm.

"The high-quality CBD extract that comes from CO2 processing commands a premium... A method that optimizes their extraction is good for the bottom line." – Custom Processing Services

3. Reduced Energy Consumption Cuts Long-Term Costs

When it comes to hemp extraction, energy bills can make or break profitability. CO2 extraction systems offer a significant edge, slashing energy costs compared to ethanol-based setups. For example, running a 1-ton-per-day CO2 facility costs about $77.61 per day in energy expenses, while a comparable ethanol system racks up a hefty $423.22 per day. Over a year, that’s roughly $2,328 for CO2 versus a staggering $12,696 for ethanol. These savings only grow as operations scale.

At larger scales, the gap in energy demands widens. A 10-ton-per-day CO2 facility requires around 2,400 amps of electrical capacity, whereas an ethanol system needs nearly 7,000 amps. Breaking it down further, processing 2,000 lbs of biomass with ethanol consumes about 6,232 kWh - with 4,408 kWh just for cooling. In contrast, CO2 systems can process 44 lbs of biomass with as little as 8.6 kWh.

"In terms of energy use, ethanol is drastically more impactful than CO2." – extraktLAB

The cost per cycle also tells a compelling story. CO2 extraction costs about $0.32 per cycle, compared to $2.56 for ethanol. Why? CO2 systems operate in a closed-loop design, recapturing and recycling the solvent, which eliminates wasteful thermal cycling. Ethanol systems, on the other hand, demand constant heating and cooling - down to -30°F - which drives up energy use.

All things considered, transitioning from ethanol to CO2 extraction for a 1-ton-per-day operation can lead to annual savings of approximately $702,000. That’s a game-changer for long-term profitability.

4. Easy Scaling for Large-Scale Production Operations

CO2 extraction systems make it simple to scale up from smaller operations - like processing 900 pounds a day - to industrial-level production without the need to overhaul your entire setup. This modular design offers a clear cost advantage for businesses trying to keep up with unpredictable market demands. It’s a setup that blends flexibility with financial sense.

Thanks to its nonflammable and non-toxic nature, CO2 extraction also speeds up regulatory approvals. Expansion permits are often processed faster compared to hydrocarbon or ethanol systems, which come with hefty requirements like Class 1 Division 1 hazardous certifications and fire suppression systems. These extra hurdles can slow down growth and inflate costs.

"It is scalable, which has allowed my business to grow along with my satisfied clients." – Mark G., Lead Toll Processor, Eden Labs

Another big win? The compact design of high-capacity CO2 extractors. For instance, a system capable of processing 844 pounds per day takes up just 48 square feet of floor space. That small footprint means you don’t need to invest in massive facilities as your production scales up.

CO2 systems also shine when it comes to adaptability. By tweaking temperature and pressure settings, producers can isolate specific cannabinoids like CBD, CBG, or THCV, depending on market trends - all without the need for new equipment. This tunability ensures that businesses can pivot quickly and efficiently, making growth smoother and more cost-effective.

5. Clean Extraction Methods Improve Market Appeal

CO2 extraction stands out for producing solvent-free products, a key selling point for health-conscious consumers. Unlike hydrocarbon methods that rely on chemicals like butane or hexane, CO2 naturally evaporates at room temperature, leaving no trace of contaminants behind. This level of purity allows brands to confidently label their hemp products as "clean" and "non-toxic", an essential distinction in the nutraceutical and personal care industries, where consumers meticulously examine ingredient lists.

But it’s not just about purity - CO2 extraction also boosts product quality by sterilizing the raw materials. During the process, bacteria, mold, and even insects in the biomass are eradicated. For brands aiming to capture the premium market, this built-in sanitization step provides a clear justification for higher price tags, appealing to buyers who prioritize quality and safety.

Another advantage lies in CO2's ability to preserve delicate terpenes and heat-sensitive cannabinoids, both of which are crucial for the "entourage effect" that many health-conscious buyers seek. Subcritical CO2 extraction, which operates at pressures under 1,083 psi and temperatures below 88°F, ensures that these fragile compounds remain intact. This meticulous preservation enhances the natural aroma and therapeutic properties of the product, strengthening brand reputation as demand for full-spectrum CBD products continues to rise.

The environmental benefits of CO2 extraction also play a significant role. As a recyclable, non-flammable, food-grade solvent, CO2 aligns with the "green" values increasingly important to consumers. These eco-friendly attributes not only build trust but also support higher pricing. Compliance with regulatory standards becomes more straightforward too, as CO2 extraction is often conducted in FDA-registered and GMP-certified facilities. This allows brands to prominently display these certifications on their packaging, further enhancing credibility. With the ability to produce CBD concentrations as high as 92%, CO2-extracted products position themselves as the premium choice in a crowded and competitive market.

Conclusion

CO2 extraction offers a smart way to save money while boosting profits in hemp production. For a 1-ton-per-day operation, CO2 extraction costs just $115 in solvents and $77.61 in energy daily. Compare that to ethanol extraction, which runs up to $3,500 for solvents and $423.22 for energy each day. This method doesn’t just cut costs - it also ensures higher cannabinoid recovery rates, allowing producers to get more value out of every harvest while keeping expenses low.

Another big win for CO2 extraction is its safety profile. Since CO2 is non-flammable and inert, facilities can avoid the hefty price tag of hazardous occupancy classifications. This can slash infrastructure costs from $200 to just $68 per square foot, saving producers about $702,000 annually. As extraktLAB puts it:

"With the highest cannabinoid recovery levels and low operating costs, CO2 extraction is usually the best choice for your manufacturing equipment foundation".

Beyond cost savings, CO2 extraction supports the creation of top-tier hemp extracts. It produces clean, solvent-free products that align with what today’s consumers want. Plus, its subcritical extraction process - running at temperatures below 88°F - helps preserve delicate terpenes, resulting in high-quality, full-spectrum products that fetch premium prices.

HALF BAK'D takes these advantages to the next level, using advanced CO2 extraction methods to craft lab-tested hemp products that meet strict quality standards. Their lineup of THC-A vapes, gummies, cartridges, and concentrates - including favorites like Sumo Gummies and Sumo Sour'd Gummies - shows their commitment to both purity and potency. By combining efficient production with exceptional products, HALF BAK'D turns these economic benefits into real value for their customers.

21 + only. Hemp-derived; contains < 0.3 % Δ-9 THC (dry weight). Effects may be delayed up to two hours. Check local laws.

FAQs

Why is CO2 extraction more cost-efficient than ethanol for hemp processing?

CO₂ extraction stands out as a cost-effective option for hemp processing when you look at the bigger picture. Sure, the upfront cost for a supercritical CO₂ system is steep - roughly double what you'd pay for an ethanol setup. But here’s the kicker: it saves you from constantly buying solvents and skips the pricey steps involved in recovering them. Plus, CO₂ extraction sidesteps the issue of hazardous waste, which means lower disposal fees.

With ethanol systems, you're looking at recovering 90–95% of the solvent, a process that drives up operating costs and requires extra materials like carbon scrubbing agents. On the flip side, CO₂ is easily recycled during extraction without adding much to your expenses. Over time, ethanol extraction can end up costing about twice as much annually as CO₂ extraction. For anyone scaling up hemp production, CO₂ extraction clearly wins the cost-efficiency game.

What are the environmental advantages of using CO2 extraction for hemp production?

CO₂ extraction stands out as a greener alternative to traditional solvent-based methods. Carbon dioxide is non-toxic, non-flammable, and doesn’t leave behind any solvent residues, making it a cleaner and safer choice for producing hemp oil. Plus, the process recycles CO₂ within the system, cutting down on hazardous waste and eliminating the need for expensive solvent recovery steps.

What’s more, CO₂ extraction helps reduce greenhouse gas emissions by reusing CO₂ captured from industrial processes. This approach not only minimizes environmental impact but also avoids the risks associated with flammable chemicals, like spills or fires, further shrinking the facility’s overall footprint. For brands like HALF BAK'D, this method aligns perfectly with a commitment to a responsible supply chain while delivering high-quality, lab-tested hemp products.

How does CO2 extraction improve the quality and purity of hemp products?

CO₂ extraction is a game-changer when it comes to crafting top-tier hemp products. Unlike methods that rely on harsh chemical solvents, this process uses pressurized carbon dioxide as a clean, non-toxic solvent. The result? A precise and efficient way to pull cannabinoids, terpenes, and other plant compounds without leaving behind any harmful residues. Once the extraction is done, the CO₂ simply returns to its gaseous state, leaving behind a pure, solvent-free extract.

The beauty of this method lies in its ability to produce ultra-concentrated extracts - often packing over 90% CBD or THC - while keeping the plant's natural terpene profile intact. These terpenes not only enhance flavor but also contribute to the product's therapeutic properties. Even better, the process can be fine-tuned for specific hemp strains, ensuring every batch hits consistent levels of potency and purity.

At HALF BAK'D, we harness this cutting-edge tech to bring you premium, lab-tested products like THC-A vapes, gummies, and concentrates. The result? A clean, trustworthy experience you can count on, every time.

21 + only. Hemp-derived; contains < 0.3 % Δ-9 THC (dry weight). Effects may be delayed up to two hours. Check local laws.